Description

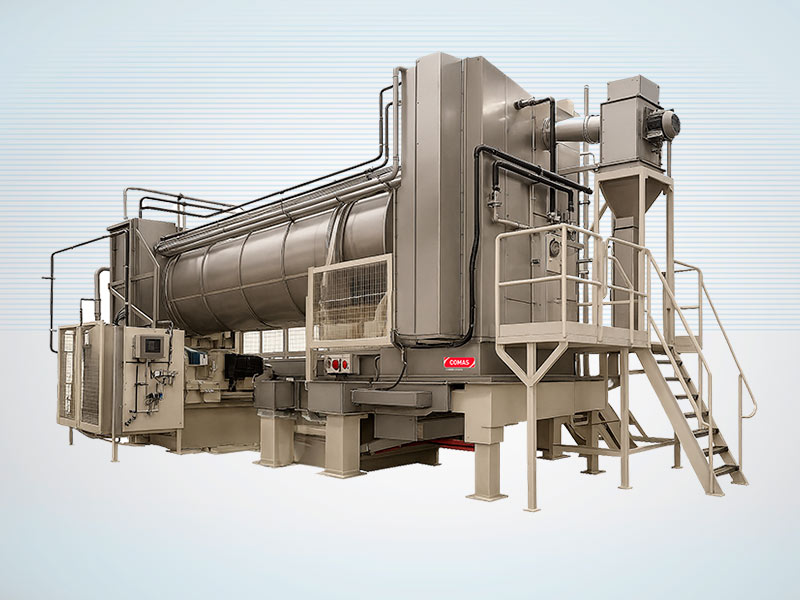

The COMAS Direct Conditioning cylinder (DCC) is the first choice option when selecting your conditioning cylinder, as our machine has been developed to provide the best loosening, opening and uniform conditioning of all types of lamina strips and leaf.Our DCC can be customised to suit your processing specification from single type lamina conditioning through to multi-grade conditioning, so that the very best processing results can be achieved for each individual grade of tobacco.

The following customised options are available:

- Variable cylinder angle inclination (Automatic or manual)

- Variable cylinder rotational speed

- Fully heated discharge hood

- Heated cylinder body

- Casing application system (DCCC)

- Internal paddle/pin geometry

- Automated cleaning system

The above options allow us to provide you with a first class conditioned product that will benefit your production throughout your entire primary process.

As the sliced segments of lamina are introduced into the cylinder, usually by means of a declined vibratory conveyor with a gentle conveying action, the product is exposed to the opening section of the cylinder process, by coming into contact with the loosening and opening paddles/pins. This, combined with the process opening steam being applied in this area, makes the slices open freely and absorb process moisture.

The next stage of the process is to apply additional moisture to the tobacco to achieve the pre-set required level, by using steam atomised water sprays, contacting the product when cascading in even free fall in the cylinder, after being rotationally lifted and released. This, combined with the continuous mass flow presented to the DCC and by lightly volumetric loading the cylinder, allows 100% product contact with the conditioning process.

Every DCC or DCCC is supplied complete with a services cubicle that houses all the utilities application systems required for the conditioning process.