Unleash the power of AI for superior bale inspection

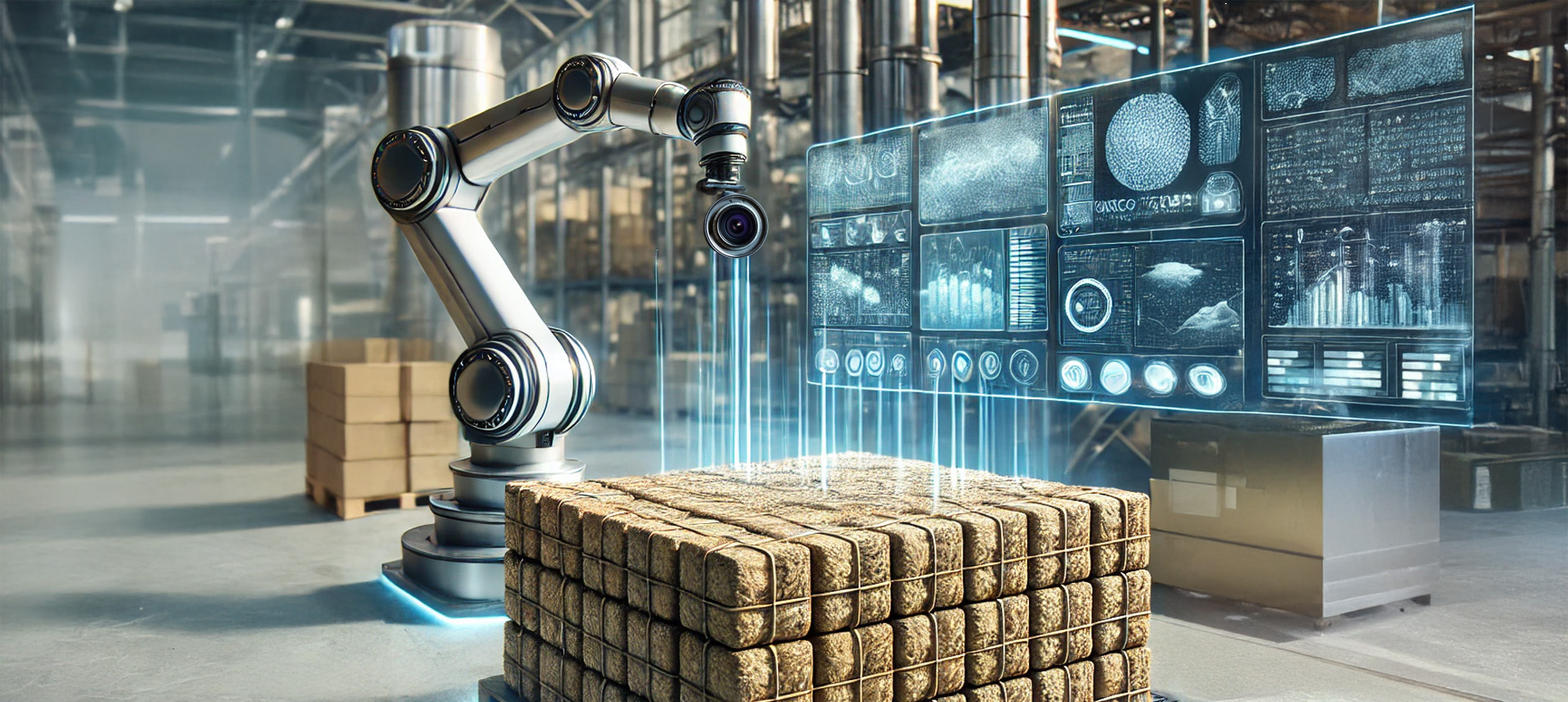

Driven by the ever-evolving technological landscape, Comas unveils its new software package fully developed to streamline the raw material analysis at the infeed of the tobacco manufacturing line.

This solution leverages the power of deep learning to provide unparalleled accuracy and human expert precision level in the automated visual inspection of tobacco bales.

Comas’ new application is specifically engineered to help manufacturers ensure the quality and consistency of their products. By utilizing advanced image recognition, the software can automatically detect physical and organic anomalies in tobacco bales, significantly reducing the risk of product recalls and improving overall quality.

Deep learning at the core

Representing a significant step forward, our software can automate the processing flow by offering performances comparable to human operators running.

A high precision camera, in combination with a robotic arm, executes a precise inspection routine covering the complete bale from different perspectives.

System results, including class probabilities and detected object positions, are displayed on the HMI in real-time. The system can automatically resolve issues or require operator confirmation, depending on specific scenarios or user-defined configurations. These configurations are fully customizable.

Advanced features and benefits to achieve excellence

Key features and benefits of the new software package include:

- Enhanced accuracy: the AI-powered system offers superior accuracy in detecting a wide range of defects, including foreign materials, discoloration, and structural damage.

- Increased efficiency: Automated inspections streamline the quality control process, reducing the time and labour required for manual inspections.

- Improved consistency: By eliminating human error, the software ensures consistent quality assessment across all batches of tobacco.

- Data-driven insights: The software generates detailed reports and analytics, providing valuable insights to optimize production processes and improve overall production quality.

Comas redefines infeed line operations, delivering speed, precision, and flexibility to meet the demands of the tobacco industry.

Contact us to discover how we can help you find the optimal solution for your specific needs, whether you're seeking a new line or an upgrade.